Dual Media SX Filters – For Organic-Free and Filtered Electrolyte

Increase copper solvent extraction efficiency while lowering cost

- Fine electrolyte filtration down to 10 microns

- Organic removal down to 2 ppm

- Single unit flow rates up to 660 gpm (150 m3/hr)

- Automatic operation

Choose SpinTek!

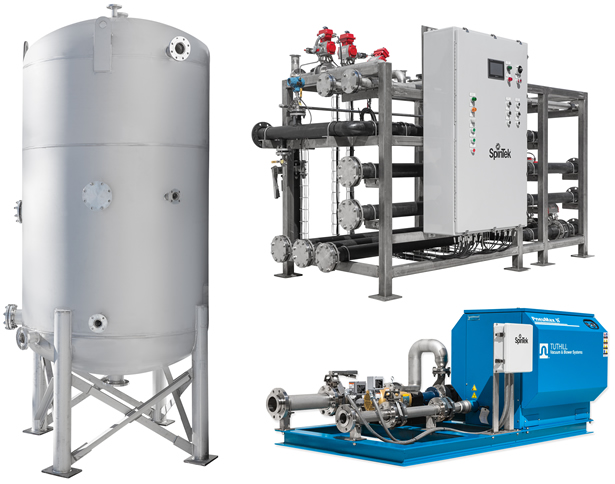

The SpinTek Dual Media SX filters are specifically designed to provide excellent organic removal and filtered electrolyte for the solvent extraction market. The filters are ruggedly designed and built to operate in the difficult environments of solvent extraction plants.

The SpinTek Dual Media SX filters are free standing, self-contained units available in a variety of standard sizes with individual unit flow rates of up to 660 gpm (150 m3/hr). Multiple units can provide for much higher flow rates. All vessels, media, piping, instruments and controls are provided for a completely automatic and operational filtration system.

Controls and Instruments

The Dual Media SX filters are automatically controlled in service, organic recovery and backwash with a PLC in a NEMA 4X housing to protect it from the environment. Custom controllers can be engineered and built to any specification for single unit or multiple unit control.

Standard instrumentation includes two stainless steel pressure gauges with seals. A vortex flow meter, automatic flow controller, delta pressure switch and organic recovery switch, all of 316L SS, are also standard.

Piping and Valves

Standard valves for the Dual Media SX filters are 316 SS butterfly with air operators. Two 316 SS sample valves are included for monitoring the system’s performance and a 316 SS safety pressure relief valve provides system protection.

Piping is manufactured of 316 SS or Drisco HDPE fusion welded and can be heat traced to prevent crystallization.

Media Filtration

The Dual Media SX filters provide for excellent removal of organic and suspended solids from the electrolyte system. The SX filters use two separate layers of media for coalescing and for filtration. The upper media layer provides for organic removal down to 2 ppm while the second media layer provides electrolyte filtration down to 10 microns.

Pressure Vessels and Skid

The Dual Media SX filter pressure vessels are constructed of 316L SS, built to the stringent ASME and NB requirements and stamped. Normal pressure vessel rating is 50 psig with higher ratings available.

Manways, tank supports and windows are standard for this filtration system and are also constructed of 316L SS. All vessel connections are standard ANSI flanges.

The Dual Media SX filters are mounted on carbon steel skids that have been blasted to SSP-10 and coated with both epoxy and polyurethane for extra corrosion protection.

Vessel Internals

Vessel internals for inlet flow, backwash and service outlet are all constructed of 316L SS. In addition, the air and service outlet internals have 316L SS screens for media containment.

Additional Standard Features

- Stainless steel ASME code pressure vessels

- HDPE

- Full instrumentation

- Custom modifications available

Custom Features

The Dual Media SX filters can be built to a wide variety of specifications. Typical options include custom controllers, alternate piping and vessel materials, such as Hastelloy, specific welding specifications and many others, to meet the demanding requirements of clients and specifying engineering firms for their industrial filtration needs.

Please contact SpinTek direct for more information on how the SpinTek Dual Media SX filters or our other hydrometallurgy products can be designed to meet any special requirements.