Desulfurization of Middle Distillate Sulfur Hydrocarbons: Gasoline, Transmix, and Diesel No. 2.

SpinTek, Inc. has developed a non-oxidized desulfurization process that is efficient and cost effective for removal of middle distillate sulfur hydrocarbons. The technology uses a cyclic process of an adsorbent to adsorb and desorb. After the adsorbent is fully loaded with sulfur compounds, the adsorbent bed is regenerated by using a simple process to detach sulfur from adsorbent surfaces using recyclable strip solution. Thus, the adsorbent bed can be changed from operating mode into regenerating mode. This Direct Extraction(DXs) process is scalable from pilot size systems up to 200,000 barrels per day (bpd) systems. This desulfurization technology can be applied to Middle Distillates: Gasoline, Transmix, and Diesel No. 2.

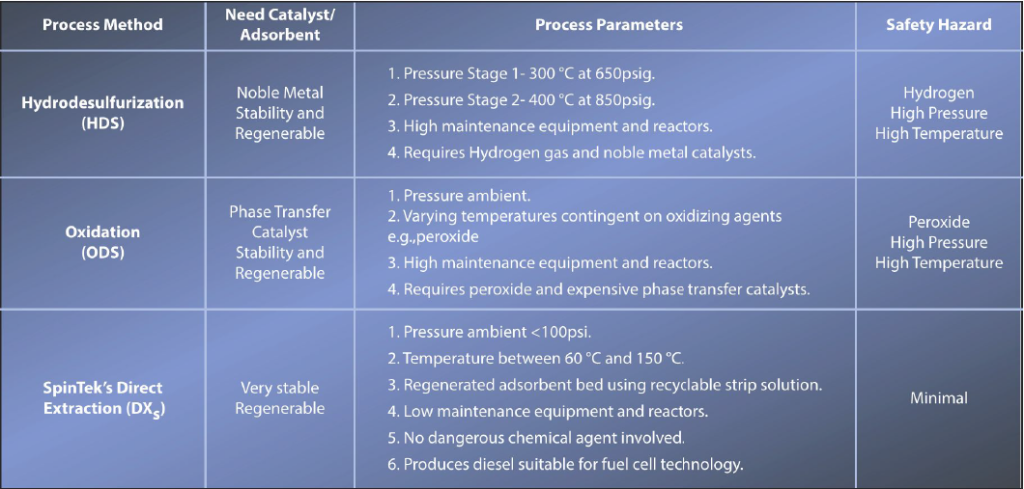

Process Comparison

Advantages

- No hydrogenation & no oxidation process requiring hazardous oxidation agents, e.g., peroxide

- No sodium hydroxide treatment

- No sulfones created; no difficult to process byproducts

- Low operating temperature <150 °C

- Low pressure <100 psi

- Stand-alone operation or a concentrator of sulfur distillates for more efficient HDS operation

- Extraction efficiency does not depend upon molecule size or structure of sulfur middle distillate (e.g., thiophene to larger than dibenzothiophenes)

- Production of Ultra Low Sulfur Diesel (ULSD)

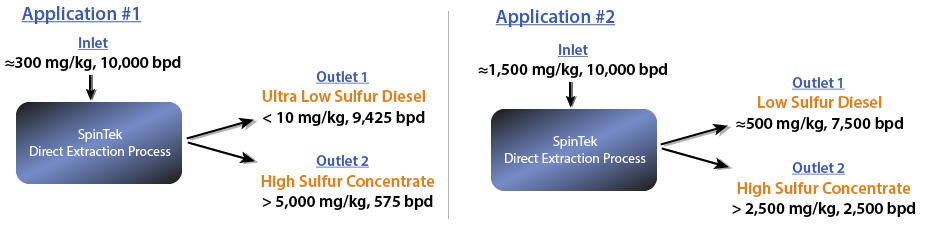

Example Applications

Process Comparison

The SpinTek DXs process removes all of the sulfur compounds in diesel nonselectively. In contrast to Oxidation, the adsorption requires no oxidation or chemical addition and any concentrated sulfur compounds can be sent, if necessary, to a hydrodesulurization(HDS) unit. Because the HDS process is more cost effective at higher sulfur concentrations, the SpinTek DXs process enables use of smaller HDS reactors for a given sulfur throughput, or alternatively, higher throughput capacity in an existing HDS unit (debottlenecking), and lower energy/operating costs and hydrogen usage.

Please contact SpinTek directly for more information on how the SpinTek DXs technology can be designed to meet any special requirements.

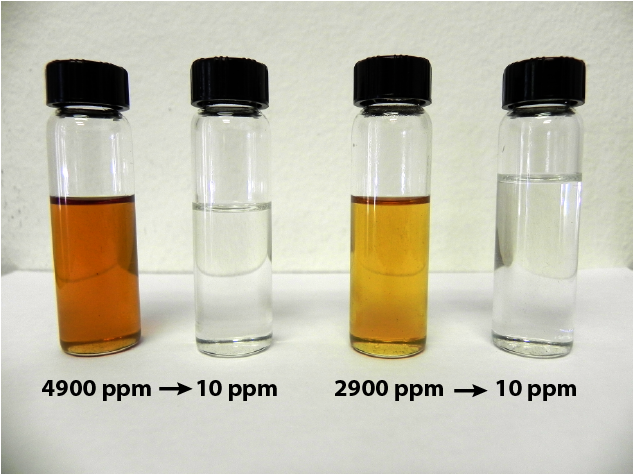

Diesel with 10 weight ppm of sulfur– product of SpinTek’s DXs technology on diesel with 4900 ppm and 2900 ppm of sulfur.

Diesel with 10 weight ppm of sulfur– product of SpinTek’s DXs technology on diesel with 4900 ppm and 2900 ppm of sulfur.

Resources