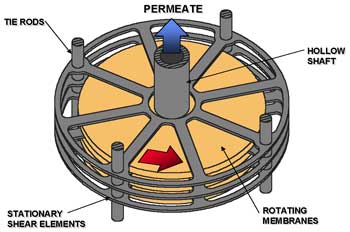

ST-II Rotary Membrane System

Rotary Membrane System for Ultra- and Microfiltration

- Rotary and high shear action

- Concentrate up to 60% solids

- Suitable for Hazardous waste streams

- Handles high level radioactive waste (HLRW) and low level radioactive waste (LLRW)

- Variety of pore sizes available

- Durable ceramic or stainless steel membranes for long life

- Explosion proof (optional)

- 316 stainless steel construction

High Shear Force for a Variety of Applications

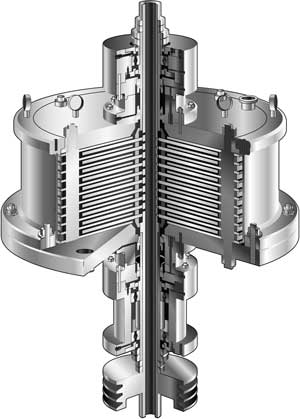

The SpinTek™ ST-II-25 is a compact cross flow membrane system that utilizes the unique SpinTek process of centrifugal action and shear force to prevent membrane fouling common to conventional systems. The ST-II-25 has wide open channels, uninhibited by mesh type turbulence promoters, allowing the system to process a wide variety of viscous solutions containing moderate to high solids. The membranes can be easily removed from the system for inspection after testing or operation. The ST-II-25 membrane surface can be fully inspected unlike most other membrane systems.

Rotary Membranes

The ST-II-25 can use a wide variety of ceramic or stainless steel membranes. Typical ceramic membranes include titania (TiO2), alumina (Al2O3), zirconia (ZrO2), or combinations of the three. Membrane pore sizes are available from 0.07 micron up to 3 microns. Stainless steel membranes are available in pore sizes from 0.1 to 10 microns. SpinTek can install custom or prototype membranes on SpinTek ST-II-25 disks.

Controls and Instrumentation

The SpinTek ST-II-25 is fully instrumented and automated for production use or pilot testing. The ST-II-25 controller is simple to operate with a NEMA 4 rated panel, lights and switches. Explosion proof ratings are also available. The standard control system includes full PLC control with an operator interface terminal for setpoint entry. Instruments include a variable frequency drive with power output, a feed pressure transmitter with PID pressure control, temperature transmitter and heat exchanger for full temperature control. Alarms are provided for customer specifications. The ST-II-25 rotor motor has a variable speed from 0 to 1200 rpm. Special instrumentation can be provided upon request.

Construction

The ST-II-25 is built to process an extensive range of feed solutions. To meet the stringent requirements of industrial filtration, all wetted parts of the ST-II-25 are manufactured of 304 SS standard. 316 SS, PTFE and Viton are optional. Special systems can be manufactured with alternate alloys and elastomers. All components of the system are rated for operation at 100 psig that allows for the use of microporous and ultrafiltration membranes.

Advantages Over Conventional Membrane Filtration Systems

The rotation of the membranes allows for the energy to be applied directly to the membrane surface where it is needed to reduce fouling and the boundary layer. Efficiency is not lost by utilizing large, high pressure pumps to recirculate mass amounts of feed solution through the system to reduce fouling. It is typical for traditional cross flow membrane filters to recirculate over 98% of the feed stream, whereby the SpinTek ST-II requires less than 50% recirculation which is used for mixing. The ST-II, due to the high rotor speed, is capable of controlling the boundary layer to effectively cause fractionation. Membrane filtration is now possible for fractionation of similarly sized particles. An example is defatting of cheese whey. Conventional static membrane systems build up a layer of solids and fat on the membrane surface which impedes the passage of pure protein through the membrane by up to 65%. The ST-II prevents this material build up on the membrane and allows passage of over 95% of the protein at the same time withholding 90%+ of the fat. Membrane filtration systems have been plagued in the past with severe membrane fouling, concentration limitations, low fluxes and device plugging. The ST-II can operate without prefilters. Pore sizes are available from 200 NMWC up to 3 microns.

Types of Membranes

- Polymeric membranes–hydrophilic and hydrophobic, low protein binding, solvent resistive

- Ceramic membranes

- Metallic membranes

Contact SpinTek directly to discuss your rotary membrane requirements.